An Oil Fired Steam Boiler is a type of boiler that uses oil as a fuel source to generate steam. These boilers are widely used in various industries, including manufacturing, food processing, chemical, and textile industries, where steam is needed for heating, power generation, and various process applications. The oil-fired boiler burns oil (such as diesel, heavy fuel oil, or other forms of petroleum) to produce heat, which is then used to generate steam.

Key Features of an Oil Fired Steam Boiler: Oil as Fuel: The primary fuel used in this type of boiler is oil, typically either light diesel oil (LDO) or heavy fuel oil (HFO). The choice of oil depends on the specific requirements of the industry, including cost, availability, and energy needs.

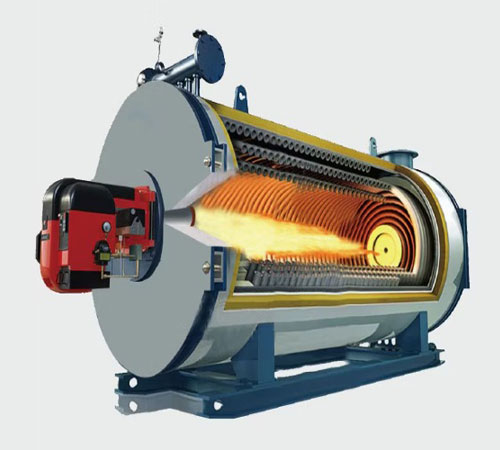

Steam Generation: The boiler uses the heat produced by burning oil in a combustion chamber to convert water into steam. This steam is then used for heating or powering various equipment or industrial processes.

Burner System: The burner is an essential component of the oil-fired steam boiler, responsible for injecting oil into the combustion chamber. The burner controls the oil flow and combustion rate to ensure efficient steam production. Modern burners come with automatic controls to optimize fuel consumption and combustion efficiency.

Heat Exchanger: The heat produced in the combustion chamber is transferred to water through heat exchanger tubes, converting the water into steam. The efficiency of the heat exchanger directly affects the performance and energy consumption of the boiler.

Pressure and Temperature Control: The steam boiler is designed to operate at various pressure levels depending on the requirements of the industrial process. Pressure and temperature gauges, along with safety valves, help monitor and maintain safe and effective operation.

Safety Features: Oil-fired steam boilers are equipped with multiple safety features to ensure they operate safely. These include:

Pressure relief valves to prevent overpressure.

Low water cutoffs to shut down the boiler if the water level drops too low.

Flame detectors to ensure proper combustion.

High-temperature alarms to alert operators to dangerous conditions.